Ensuring Health Safety: Plastic Card Production Standards

Table of Contents []

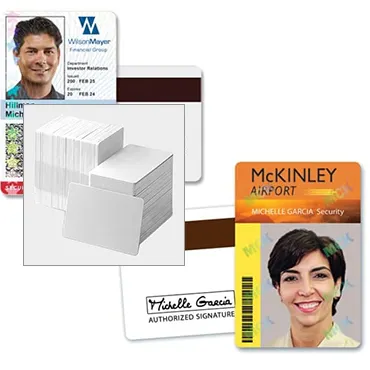

Health Safety Plastic Card Production

Health and Safety Practices in Plastic Card Production at Plastic Card ID Ensuring the safety of those involved in the manufacturing process, as well as the well-being of the end-users, is a responsibility we take very seriously at Plastic Card ID . Our commitment to upholding robust health and safety standards is part of our promise to deliver high-quality products nationwide. For any inquiries or to place an order, you can easily reach us at 800.835.7919 .

Comprehensive Training for Workplace Safety

To maintain a safe working environment, we provide comprehensive training to all our employees. This training covers every aspect of the manufacturing process, from handling raw materials to operating machinery. We believe that an informed workforce is an empowered one, capable of recognizing and mitigating risks before they become problems.

Moreover, we regularly revise our training programs to ensure they reflect the latest safety standards and technology advancements. This way, our team is always equipped with the knowledge they need to work safely and efficiently.

Regular Safety Drills and Emergency Response

We conduct regular safety drills to ensure all our workers know how to respond in the case of an emergency. Practice makes perfect, and by routinely simulating potential scenarios, we can guarantee a swift and organized reaction if it's ever needed.

Emergency response plans are in place for a variety of situations. Our employees are well-versed in these protocols, helping to ensure everyone's safety and the quick resumption of normal operations.

Maintaining a Clean and Organized Workplace

A clutter-free work environment is a safer work environment. At Plastic Card ID , we emphasize the importance of cleanliness and organization. Daily checklists ensure that each workstation is tidy and that walkways are clear of any obstructions.

This not only helps prevent accidents but also promotes productivity. A well-ordered space allows our employees to focus on their tasks without unnecessary distractions or hazards.

Ongoing Safety Evaluations and Improvements

Our commitment to safety extends beyond initial training. We regularly evaluate our safety procedures and seek ways to improve. Through these evaluations, we identify potential hazards and implement preventive measures to address them.

Feedback from our team is invaluable during these evaluations. By listening to those on the front lines, we can make effective changes that promote a secure working environment for everyone.

State-of-the-Art Equipment and Machinery

To ensure both the safety of our workers and the quality of our products, we invest in state-of-the-art equipment and machinery. These modern tools are designed with safety features that help to prevent accidents, reducing the risk of injury.

Regular maintenance schedules are strictly adhered to, ensuring that all equipment operates at peak performance and safety levels. Employees are trained to recognize any warning signs of malfunction, and any concerns are immediately addressed by our in-house maintenance team.

Advanced Safety Features on Machines

Our machines come equipped with safety guards, emergency stop buttons, and other features designed to protect our workers. These features are checked periodically to ensure they function properly and provide the necessary protection.

Employees are also trained to use personal protective equipment (PPE) when operating machines. This PPE serves as an extra layer of defense against potential hazards inherent to the production process.

Ensuring Quality Control

Quality control is not just about the final product; it's about maintaining a safe production line. By closely monitoring our machinery and processes, we ensure that everything runs smoothly, minimizing the risk of accidents.

Our quality control team works tirelessly to inspect all aspects of production, guaranteeing that our health and safety standards are always met or exceeded.

Preventive Maintenance Program

A rigorous preventive maintenance program is in place to avoid equipment breakdowns that could pose safety risks. Through regular inspections and servicing, our machinery is kept in top condition.

This approach to maintenance is proactive rather than reactive, significantly reducing the chance of unexpected equipment failure and the safety concerns that accompany such events.

Eco-Friendly Materials and Procedures

At Plastic Card ID , our concern for health and safety extends to the environmental impact of our production. We choose eco-friendly materials that are safe not only for our workers but also for our customers and the planet.

We utilize processes that minimize waste and reduce hazardous emissions. By taking these steps, we ensure that our production is sustainable and that we are doing our part to protect the environment for future generations.

Use of Non-Toxic Materials

We are committed to using non-toxic materials in our production processes. These materials are less likely to cause health issues and are safer to handle, providing peace of mind for both our workers and customers.

Improving the safety of our materials also has the added benefit of enhancing the durability and quality of our plastic cards, making them safer and more reliable for end-users.

Recycling and Waste Reduction Initiatives

Part of our dedication to eco-friendly production involves recycling and waste reduction. Excess materials are repurposed or recycled whenever possible, significantly cutting down on the waste we produce.

By streamlining our processes and using materials efficiently, we not only reduce our environmental footprint but also optimize our production costs. This allows us to pass on the savings to our customers without compromising on quality or safety.

Minimizing Environmental Harm

We have implemented measures to minimize the environmental harm that can arise from plastic card production. These encompasses everything from managing energy use in our facilities to carefully disposing of materials that cannot be recycled.

Though plastic cards are our specialty, we remain conscious of our environmental responsibilities and are continuously searching for ways to reduce our ecological impact while upholding the high standards our customers expect from us.

Stringent Quality Assurance for Consumer Safety

Our quality assurance processes are designed to ensure that every card produced meets not only our exacting health and safety standards but also complies with industry-wide safety regulations. This commitment to quality protects both the end-user and the integrity of our brand.

We subject our products to rigorous testing, ensuring they are free from defects and safe for their intended use. Our customers trust us to provide high-quality, dependable products, and that's a responsibility we take very seriously.

Compliance with Industry Standards

We maintain strict adherence to industry standards for plastic card manufacturing. These standards are in place to protect consumers and ensure that products are safe and reliable.

By meeting or exceeding these benchmarks, we guarantee that our cards are of the highest quality and safety. Our compliance is regularly verified through third-party audits and internal reviews.

Regular Product Testing

Our comprehensive testing protocols encompass all stages of production. We test for durability, functionality, and safety to make sure that each card is ready for the rigors of day-to-day use.

From resistance to wear and tear to ensuring that the card data is securely embedded, we leave no stone unturned when it comes to protecting our customers and maintaining their confidence in our products.

Feedback Loop for Continuous Improvement

We have established a robust feedback loop that allows us to continuously improve our products. Customer feedback is taken seriously, and we are quick to address any concerns that are raised.

Not only does this practice help us maintain high safety standards, but it also fosters an environment of ongoing innovation and development within our company.

Accessible Customer Support and Services

Providing excellent customer service is integral to our operation. At Plastic Card ID , we ensure that our team is readily available to answer any questions and assist with new orders. Our nationwide service means that no matter where you are, we're here to help you. You can reach us easily at 800.835.7919 .

We're also dedicated to building strong relationships with our clients. By understanding their unique needs, we can offer customized solutions that prioritize safety and quality.

Quick Response to Inquiries

Whether a question arises about our products, an order, or our safety practices, we are quick to respond. Our customer support team is trained to provide clear, helpful information.

Timely responsiveness ensures that our clients have all the data they need to make informed decisions about their plastic card needs without any unnecessary delay.

Customized Orders Handled with Care

We handle each order with meticulous attention to detail, ensuring that the specific requirements of our customers are fully met. Whether it's a bulk order or a specialized request, we apply the same rigorous safety and quality standards.

Customization doesn't come at the cost of the safety or quality. Our advanced systems and processes allow for personalization while maintaining the highest safety protocols.

Follow-Up Services for Client Satisfaction

After a purchase, we continue to offer our support and services. Follow-up calls and satisfaction surveys are a part of our commitment to outstanding customer service.

This level of care not only ensures that our clients are happy with their products but also allows us to gather valuable feedback that can be used to further enhance safety and quality across all aspects of our business.

Our Pledge to Uphold Safety Standards

At Plastic Card ID , the health and safety of our workers and the integrity of our products are paramount. We pledge never to compromise on these critical aspects of our business. From the first step in our manufacturing process to delivery of the final product, and beyond, our dedication to safety and quality shines through.

We invite you to experience the commitment and care that go into every card we produce. Whether for new orders or any questions, our nationwide service is at your fingertips. Speak with us today at 800.835.7919 to learn more about how we can provide you with safe, quality plastic card solutions.

Commitment to Continuous Improvement

is constantly striving to improve safety standards. We integrate both the latest industry practices and innovations spearheaded by our own research and development.

By continually refining our health and safety practices, we not only adhere to current regulations but also anticipate and prepare for future advancements.

Transparency in Our Operations

Transparency is key to building trust with both our employees and customers. We openly share information about our safety practices and invite constructive feedback.

Keeping an open dialogue about our processes reassures all stakeholders of our unwavering commitment to health and safety in plastic card production.

About Us

Plastic Card ID is a leader in the plastic card manufacturing industry, providing robust, safe, and high-quality card solutions to a diverse range of clients nationwide. We take pride in our craft and are dedicated to delivering only the best to our clients.

If safety, quality, and reliability are what you seek in a card manufacturer, you've come to the right place. We look forward to assisting you further at 800.835.7919 .

In conclusion, Plastic Card ID is committed to the safety and satisfaction of everyone involved - from our hardworking employees to the end-users of our products. Our industry-leading practices in health and safety ensure that we not only meet but exceed the expectations of a trusted plastic card provider. We encourage you to reach out to us with any queries or when you're ready to place your next card order. You can always count on us for reliable service, quality products, and safety that secures. Give us a call at 800.835.7919 , and let us provide you with the outstanding service and products you deserve.Previous Page